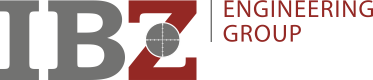

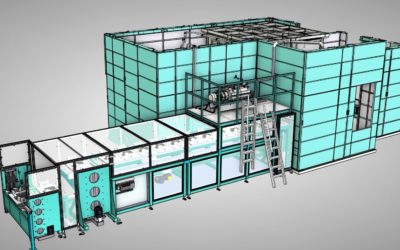

A project made for an automotive manufacturer.

Station for the extrusion of steel caps used as explosive charges for airbags. Time of one tact of work is 2 s.

Scope of work:

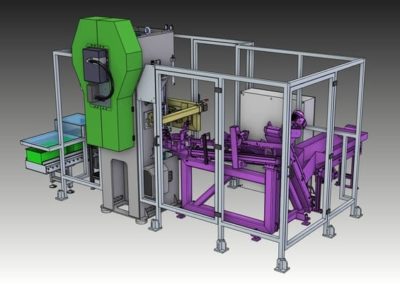

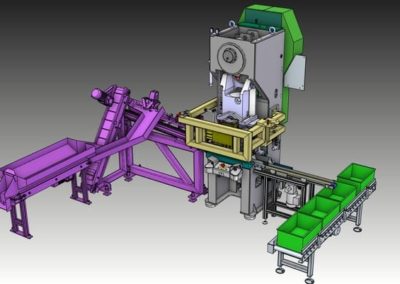

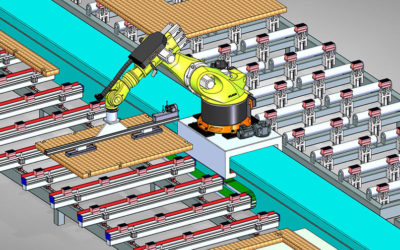

- Designing a gripper unit for transferring extruded elements into subsequent press positions. Cast 4 times in the press.

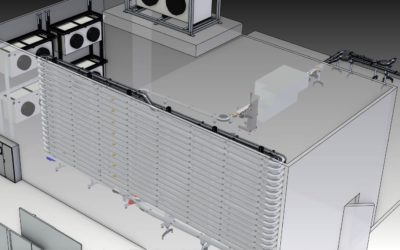

- Design of the final conveyor together with the system rejecting faulty parts

- Integration of the system into one coherent whole unit. The customer supplied system components: custom-made tools and purchased parts (raw molding sorter, press).