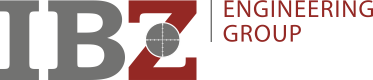

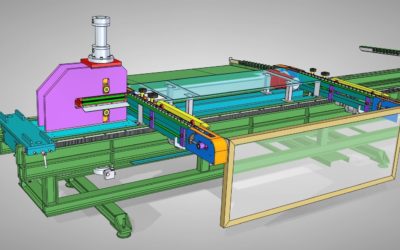

Two-level transport system with buffer for a small pallet serving system and automatic line for cleaning crankshafts. The crankshafts are delivered to the conveyor by a robot. The pallet is fed to the roller conveyor and directed to the...

Our projects

„You should be optimistic at the beginning of the job and critical at the end.”

Ludwik Hirszfeld

Our main goal is to provide our customers with the highest quality service. Close cooperation with our clients helps us to achieve it. It allows us to get to know their expectations in detail, which in effect enables us to successfully implement even the most complex projects. The best confirmation of the effectiveness of the adopted strategy is long-term trade relations with partners in Poland and abroad.

Due to the number of completed projects, we can’t boast about all of them. We are also bound by confidentiality agreements with some of our Clients, which also exclude the possibility of presenting the effects of our work. However, we hope that the presented projects will help you learn about our skills.

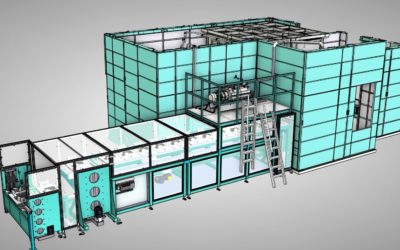

Processing centre for the production of wooden panels

The 24 x 3.5 m boards for the production of wooden houses are delivered to the machine by overhead crane. Special grippers are used to fix the position of the board on the machine. Then the board is processed by means of a robot with...

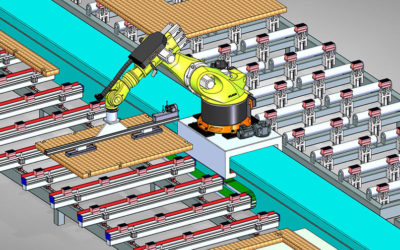

Cheese spread cooling tower

Multi-storey tower for cooling cheese from production to storage temperature. The cheeses are produced on two production lines and packed in round packs which are picked up by a transport system and collected in one thread. Each of the...

Metal airbag capsule press

A project made for an automotive manufacturer. Station for the extrusion of steel caps used as explosive charges for airbags. Time of one tact of work is 2 s. Scope of work: Designing a gripper unit for transferring extruded elements into...

Board finger joints control machine

A machine for checking the quality of finger joints of boards intended for production of shutter boards and I-beams. All boards used for production of these elements are subject to quality control. The machine checks boards of different...

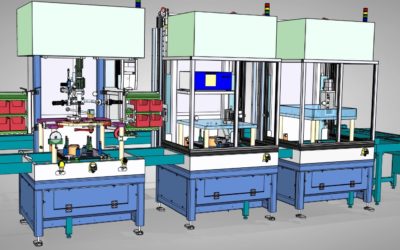

Assembly line for electric engines for hybrid cars

E-Drive mounting line - GKN/SDS On the first workstations, the gearbox elements - shafts, covers, park lock mechanism - are pre-assembled. Pre-assembled subassemblies are delivered to the transport line where the final assembly of the...

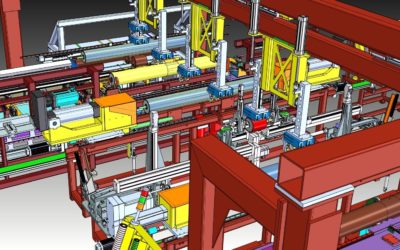

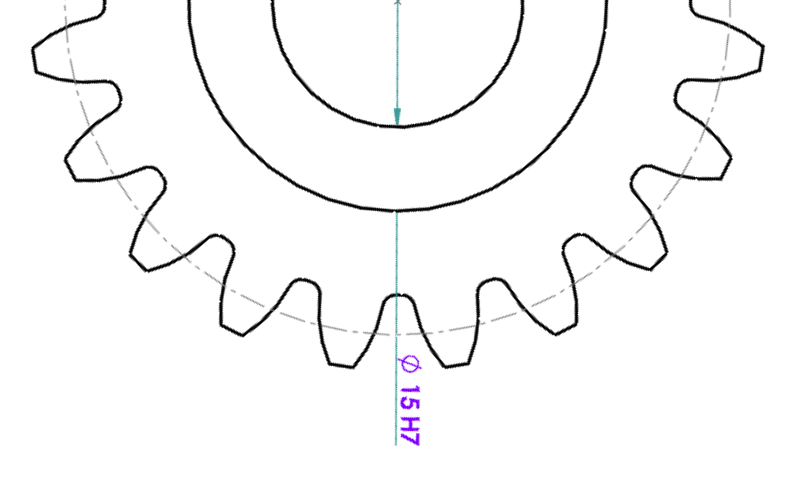

Conveyor roller production line

Fully automatic line on which rolls with diameters of 40 - 120 mm and lengths of 200 - 1800 mm are assembled. The assembly process consists of: assembly of roll axles, mounting of bearings, assembling the circlips, installation of sealing...

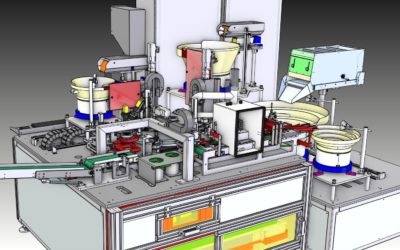

Automatic machine for simering assembly

Fully automated assembly line designed for automotive industry customer. The line is used for mounting spring rings on sealing rings and for final visual inspection. Ring dimensions: from D=20 to D=68 mm. In total 8 different types of...

Machine for final fuel filter inspection

The fully automatic line on which the final inspection of several types of fuel filters takes place. The control process includes: Removing the protective covers from the fuel inlet and outlet connections Blowing the filter with clean air...