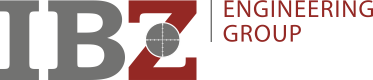

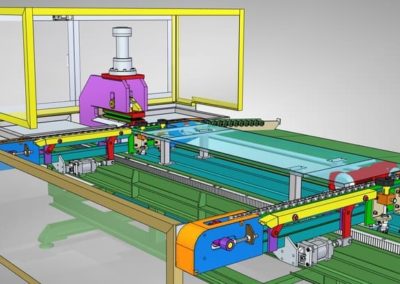

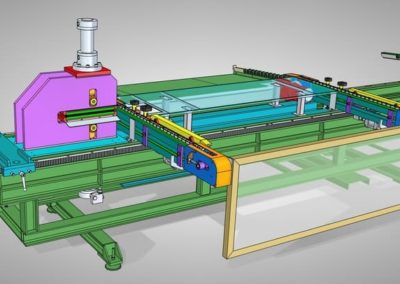

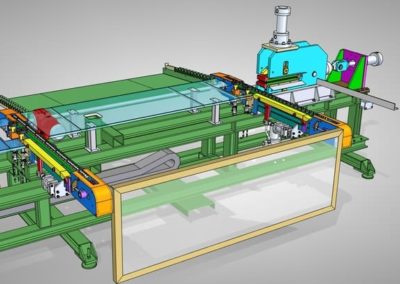

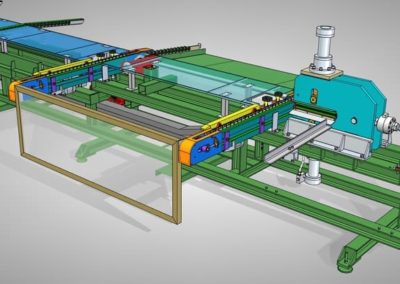

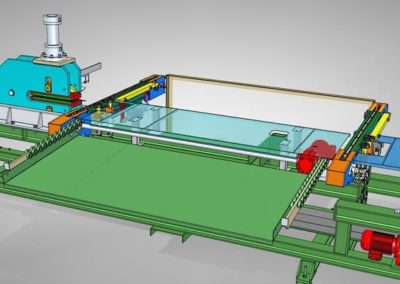

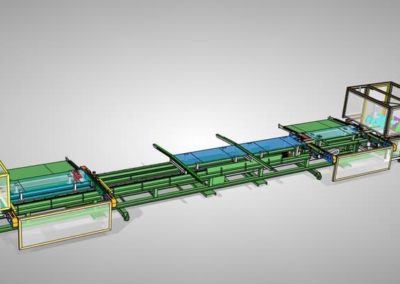

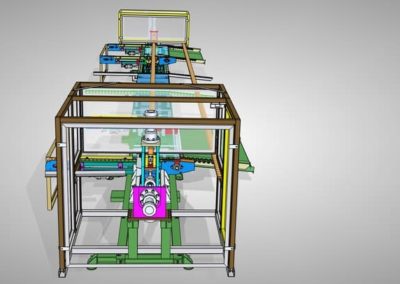

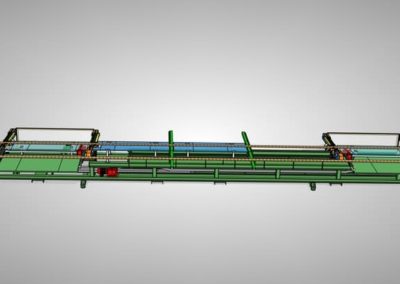

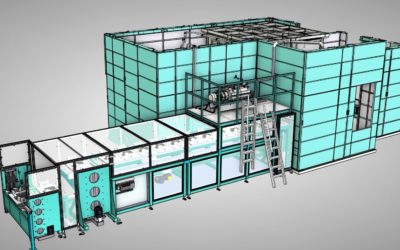

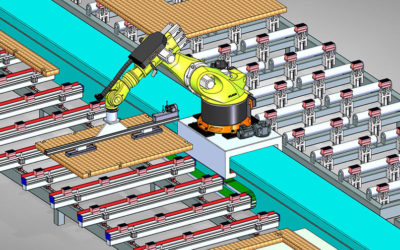

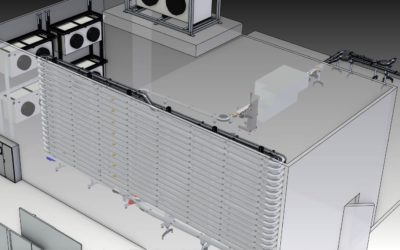

A machine for checking the quality of finger joints of boards intended for production of shutter boards and I-beams. All boards used for production of these elements are subject to quality control.

The machine checks boards of different cross-sections and from 6 m to even 12.1 m long. The maximum tensile force the machine can exert is 100 kN. The board grippers are made in such a way that no imprints are left on the boards with a depth greater than 1 mm. In addition, special gripper pads for checking already planed boards are supplied. They do not leave any prints in the wood. The capacity of the machine is 6 checking cycles per minute.

Scope of work:

- Creating a board inspection concept in accordance with ÖN B4125.

- Design of a complete machine with delivering and receiving conveyor

- Selection of hydraulic and pneumatic components

- Frame strength calculations

- Manufacturing documentation (workshop drawings, assembly drawings, BOM)