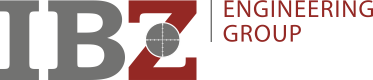

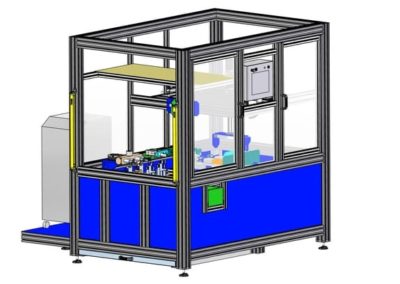

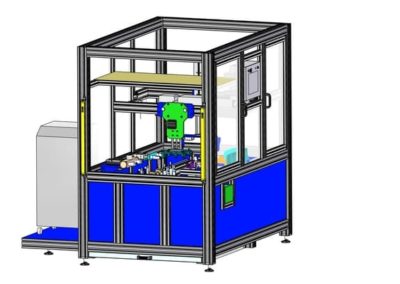

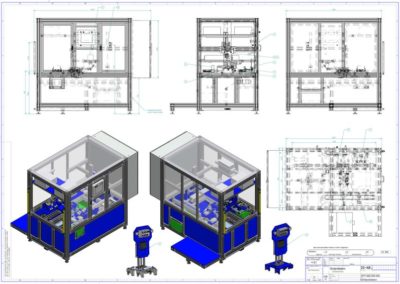

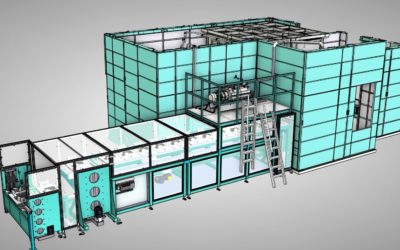

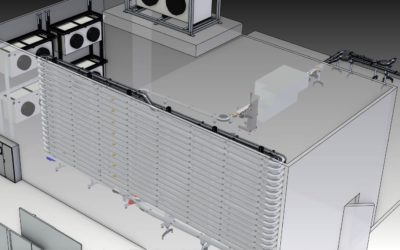

The fully automatic line on which the final inspection of several types of fuel filters takes place.

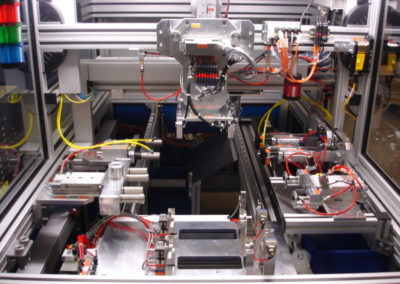

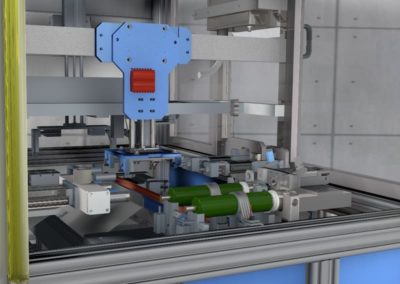

The control process includes:

- Removing the protective covers from the fuel inlet and outlet connections

- Blowing the filter with clean air

- Checking electrical heater

- Verifying that the filter contains all the necessary parts

- Checking the product for leaks

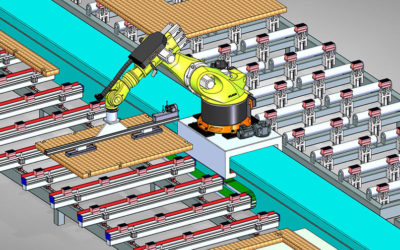

- Laser marking of correct parts and their return to the operator

NOK parts are rejected automatically.

Due to the need to shorten the tact time of the device, the machine inspects two filters at the same time. The employee picks up checked and labeled filters and puts them in the transport box. Then he inserts 2 new filters into the machine and starts the checking process again.

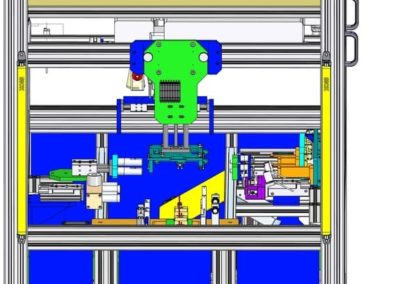

The line consists of:

- Replaceable workpice carrier

- Control and measuring tools (checking pressure, electrical contact, checking if all filter parts are correctly assembled)

- Marking laser

- Automatic collector for NOK parts

The scope of work included the design of the whole machine and completing the project documentation.