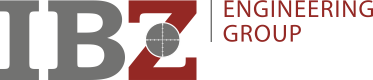

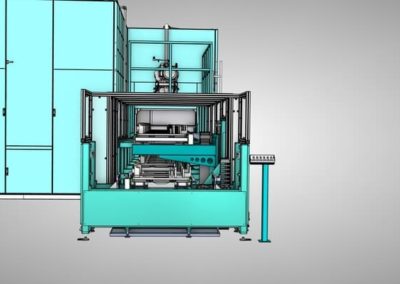

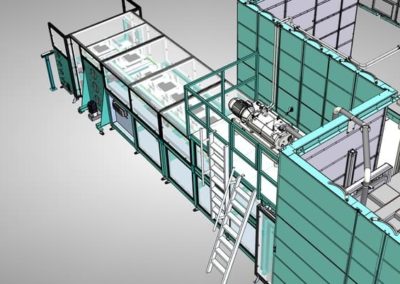

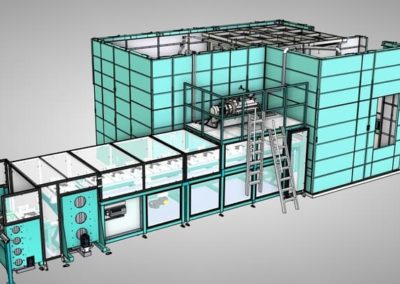

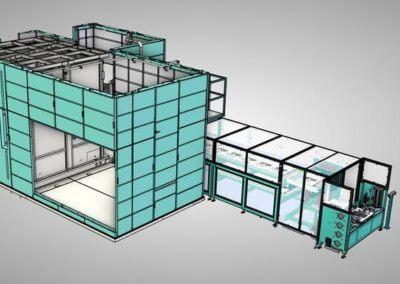

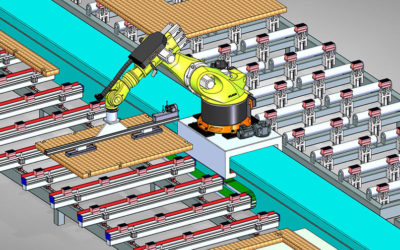

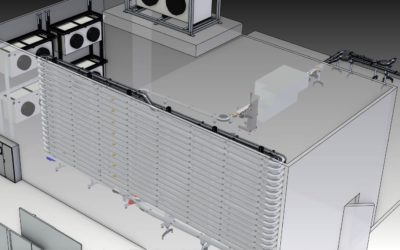

Two-level transport system with buffer for a small pallet serving system and automatic line for cleaning crankshafts.

The crankshafts are delivered to the conveyor by a robot. The pallet is fed to the roller conveyor and directed to the cleaning machine. In the cleaning machine another robot picks up the item to be cleaned and delivers it further. The pallet is lowered on the lower floor and returned to its initial position, where it is moved to the upper level by the next lift. A special pallet exchange system and a separate shaft storage area allow for a flexible work system of the robots delivering and receiving crankshafts. This is a universal pallet for 6 types of crankshafts.

Scope of work

- Creating a material flow concept

- Design of the complete machine (3D models)

- Selection of pneumatic components

- Manufacturing documentation (2d drawings, assembling drawings, BOMs)