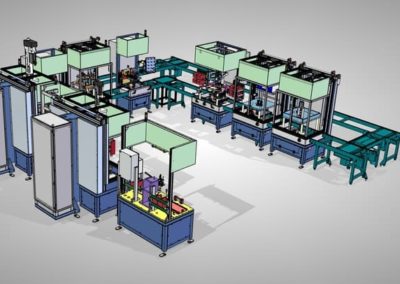

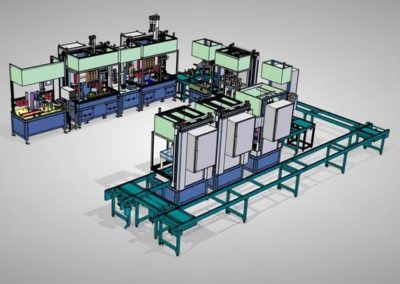

E-Drive mounting line – GKN/SDS

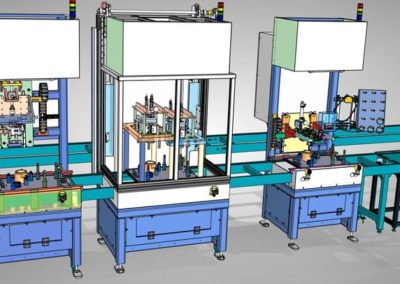

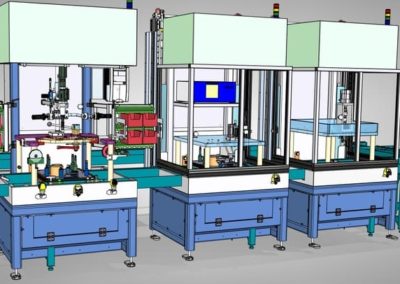

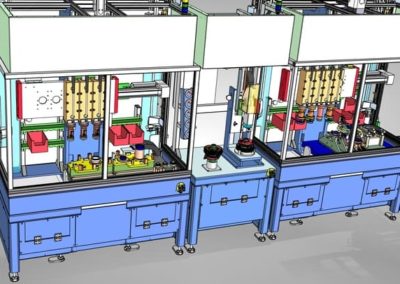

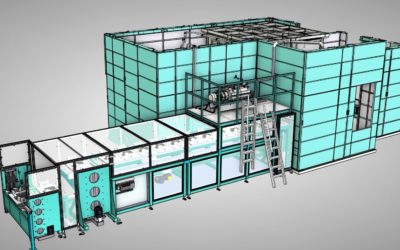

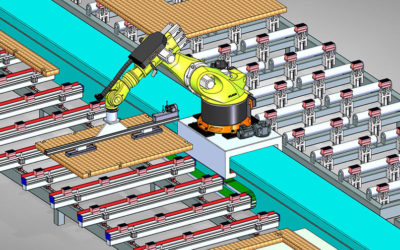

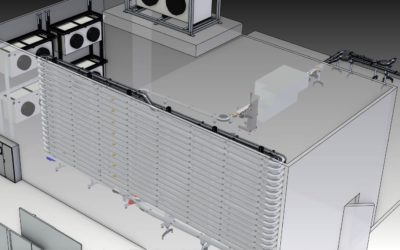

On the first workstations, the gearbox elements – shafts, covers, park lock mechanism – are pre-assembled. Pre-assembled subassemblies are delivered to the transport line where the final assembly of the engine takes place. The line also includes fully automatic checking and measuring stations and automatic and semi-automatic assembly stations (bearing presses, rings, twisting stations, manipulators). Project size 5500 design working hours, realized parallel to the final phase of product development. Work started on the product in the pre-series phase. The serial product was approved for production after the design was completed. This required a design approach that allowed for minor changes to the product without the need to make changes to the machines.

Scope of work:

- Completion of the concept of assembling process of the electric engine (line layout)

- Design of individual production line stations

- Design of the Bosch transport system and workpiece carrier

- Coordination of the work of the design team

- Concept and 3D model acceptance at the customer’s plant

- Manufacturing documentation

- Risk analysis

- Manuals and station descriptions

The project was conducted in an international environment, entirely in English.