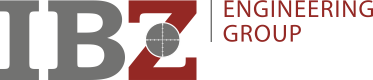

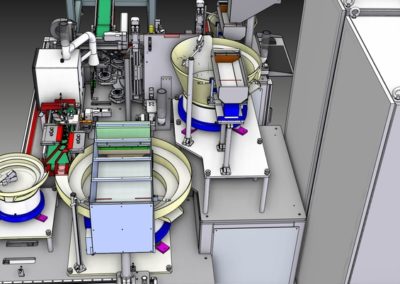

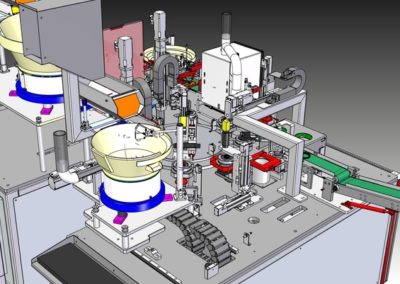

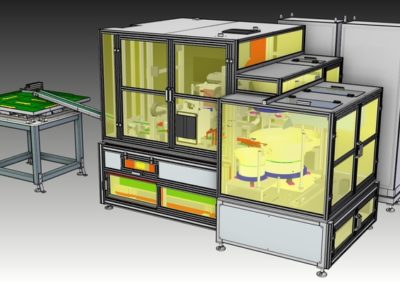

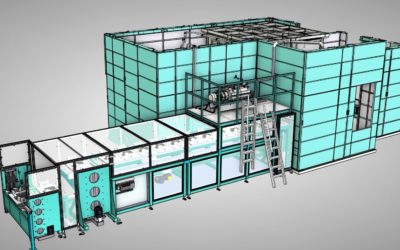

Fully automated assembly line designed for automotive industry customer.

The line is used for mounting spring rings on sealing rings and for final visual inspection. Ring dimensions: from D=20 to D=68 mm. In total 8 different types of rings are mounted on the line. Extension of the series is possible. The machine is manually reset. The maximum set-up time is 15 minutes.

Delivery, separation of bodies and springs takes place automatically. Receiving of finished rings is done by means of a gate. This way enables an uninterrupted production process.

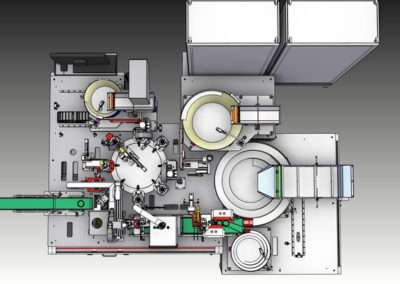

The line consists of the following elements:

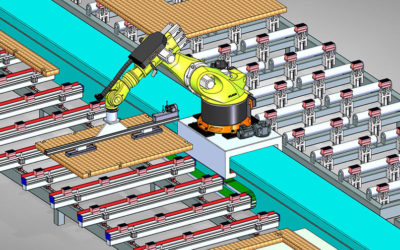

- a turntable with exchangeable nests

- automatic ring body feed system with ring alignment control

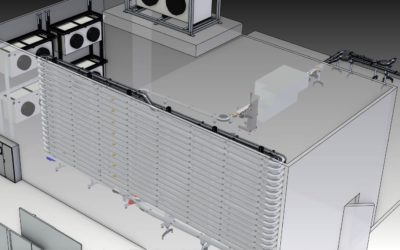

- body cleaning device with ionized air

- automatic springs supply and installation system

- visual inspection tools

- automatic sorter for OK and NOK parts.

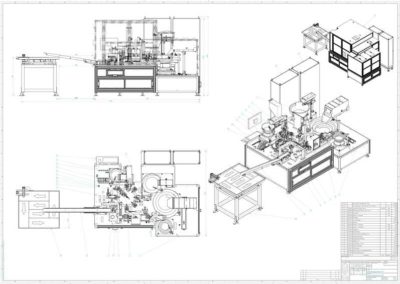

The IBZ’s task was to design the whole machine and complete documentation.