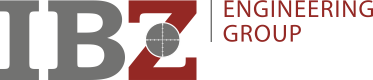

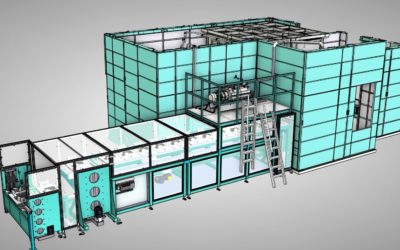

Multi-storey tower for cooling cheese from production to storage temperature.

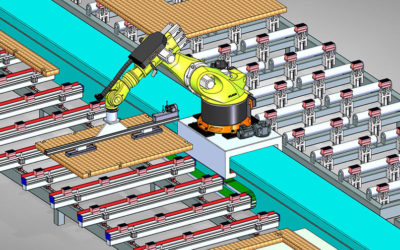

The cheeses are produced on two production lines and packed in round packs which are picked up by a transport system and collected in one thread. Each of the packages is weighed during transport. Through the sluice, they are transferred to a cooling chamber with a temperature of approx. -20°C. They stay there until they reach the appropriate temperature. Next, the cheeses are transported to the warehouse, where they are packed into the collective packages and stored at a temperature of approx. 4°C.

Scope of work:

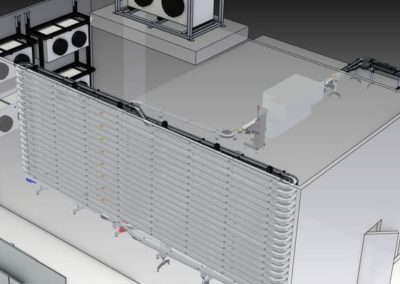

- Design of the entire transport line

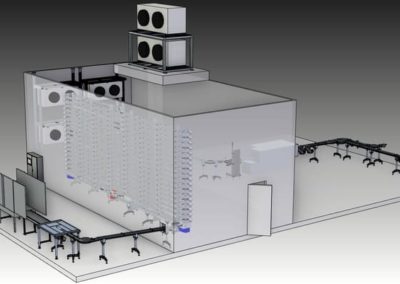

- Cooling tower design

- Selection and supervision of the delivery of refrigeration components

- Project management

- Preparing the complete manufacturing documentation