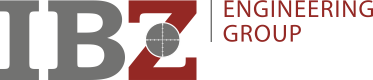

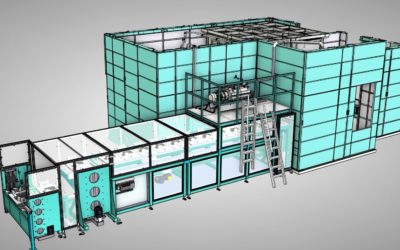

Fully automatic line on which rolls with diameters of 40 – 120 mm and lengths of 200 – 1800 mm are assembled.

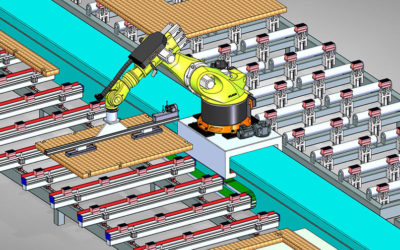

The assembly process consists of:

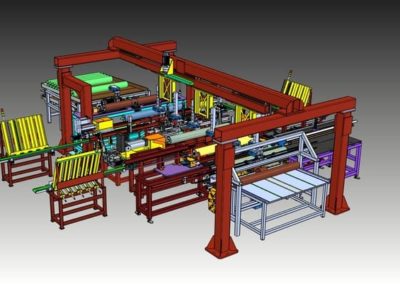

- assembly of roll axles,

- mounting of bearings,

- assembling the circlips,

- installation of sealing rings,

- balance and bearing resistance checks.

Bearings, sealing rings and a circlip are delivered automatically. An employee is only needed to feed in the axles and rollers and to operate the bearing and ring storage. The line does not need to be reset.

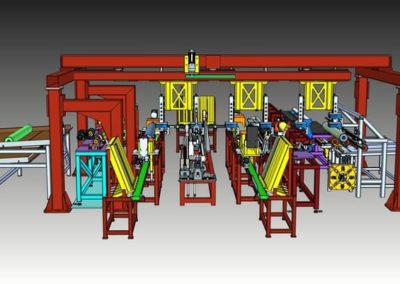

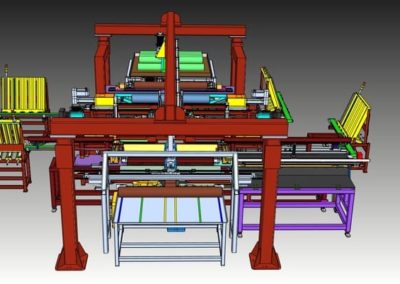

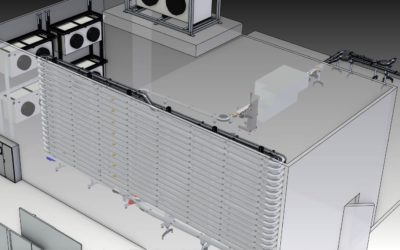

The line consists of:

- transport system

- the feed table for rolls and axles

- receiving table of the finished rolls

The scope of work carried out by IBZ included designing the whole line and preparing full documentation.